Why does PLA+PBAT become the main raw materials for biodegradable bags?

Why does PLA+PBAT become the main raw materials for biodegradable bags?

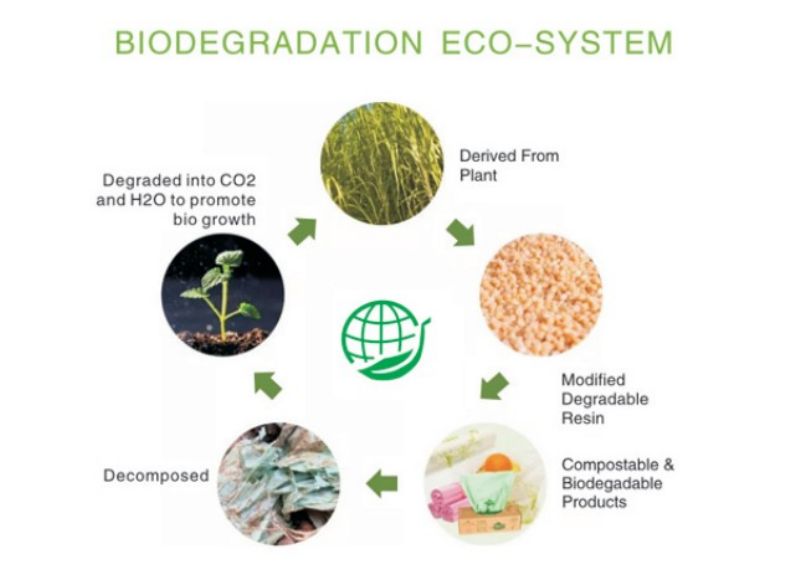

As global environmental awareness increases, the demand for degradable plastic bags continues to grow. Among many degradable materials, PLA and PBAT have become the preferred raw materials for making degradable plastic bags due to their unique properties and advantages.

PLA, whose full name is polylactic acid, is a biodegradable material made from starch raw materials extracted from renewable plant resources (such as corn starch).

PLA has good biocompatibility and biodegradability, and can be completely degraded by microorganisms in nature, eventually producing carbon dioxide and water, without causing pollution to the environment. In addition, PLA also has excellent mechanical properties and processing properties, and can be made into films, fibers and injection molded parts. It is widely used in packaging, medical, agriculture and other fields.

PBAT, or polybutylene adipate/terephthalate, is a thermoplastic biodegradable plastic. PBAT has good biodegradability, thermal stability, mechanical properties and processing properties, and can be widely used in packaging, agricultural mulch films, fibers and non-woven fabrics and other fields. The biodegradation process of PBAT mainly relies on the action of microorganisms, and is eventually decomposed into carbon dioxide and water, without causing long-term effects on the environment.

PLA, whose full name is polylactic acid, is a biodegradable material made from starch raw materials extracted from renewable plant resources (such as corn starch).

PLA has good biocompatibility and biodegradability, and can be completely degraded by microorganisms in nature, eventually producing carbon dioxide and water, without causing pollution to the environment. In addition, PLA also has excellent mechanical properties and processing properties, and can be made into films, fibers and injection molded parts. It is widely used in packaging, medical, agriculture and other fields.

PBAT, or polybutylene adipate/terephthalate, is a thermoplastic biodegradable plastic. PBAT has good biodegradability, thermal stability, mechanical properties and processing properties, and can be widely used in packaging, agricultural mulch films, fibers and non-woven fabrics and other fields. The biodegradation process of PBAT mainly relies on the action of microorganisms, and is eventually decomposed into carbon dioxide and water, without causing long-term effects on the environment.

PLA and PBAT were chosen as raw materials for degradable plastic bags mainly because they have the following advantages:

1. Good biodegradability: PLA and PBAT can be degraded by microorganisms in the natural environment and will not cause long-term pollution to the environment.

2. Renewable resources: PLA is derived from renewable plant resources, and PBAT can also be produced through blending or chemical synthesis, which is sustainable and environmentally friendly.

3. Excellent performance: PLA and PBAT have good mechanical properties and processing properties, and can meet the needs of different application scenarios.

4. Wide range of application fields: PLA and PBAT are widely used in packaging, medical, agriculture and other fields, and have broad market prospects.

To sum up, PLA and PBAT have become ideal raw materials for making degradable plastic bags due to their unique properties and advantages.

Itchen Packaging produces high quality biodegradable products through a series of mature processes. It is believed that with the continuous improvement of environmental awareness and the continuous development of degradable material technology, degradable plastic bags will be used in more fields in the future, and Itchen Packaging will also make greater contributions to environmental protection.

Latest News

Latest News

Contact Us

Tel: +86 185 2653 3984

E-mail: [email protected]

Add: 56 Huaidong Road, Beichen District, Tianjin, China

Mail inquiry

Mail inquiry